Overview

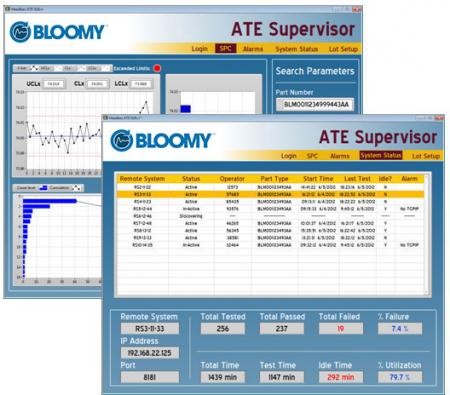

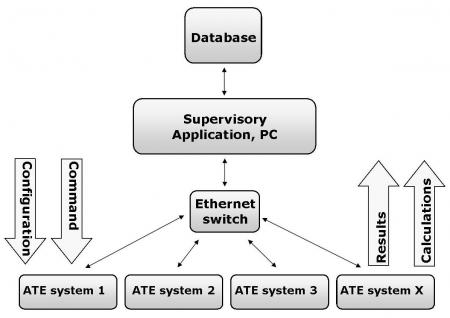

Bloomy's Headless ATE is an automated test platform that is extremely simple to operate and does not require a PC. It consists of a 3U enclosure containing National Instruments' Single-Board RIO with LabVIEW software, a power supply, and preexisting commercial-off-the-shelf (COTS) test instruments. The front panel contains just a couple of mechanical push buttons, and pass and fail LEDs. The test program, instrument configuration settings, and test limits are maintained by ATE Supervisor, a supervisory application that runs on a networked PC. The simplicity of Bloomy's Headless ATE System is beneficial to manufacturing facilities that have multiple manual test stations, operator usability concerns, or a low volume and high product mix requiring frequent changeovers. The configuration management and control capabilities are ideal for regulated industries such as aerospace, medical, and transportation.

Features

- Simple operator panel consists of mechanical buttons and Pass/Fail LED indicators

- Compact 3U enclosure

- NI Single-Board RIO embedded controller

- Test VIs developed using LabVIEW Real Time and FPGA

- 16 16-bit analog inputs, 4 16-bit analog outputs, up to 100 DIO lines

- Integrated 10/100BASE-T Ethernet, RS232 serial, RS485 serial, USB, CAN, and SDHC ports

- Eliminates PC including monitor, keyboard, touchscreen and mouse

- Centralized configuration of all instruments, test programs, and pass/fail limits via ATE Supervisor

- System clock time-stamps important test activities

Benefits

- Reduces the possibility of operator error, and minimizes operator training

- Repeatable setup and configuration of all test stations

- Error-free data recording and analysis

- Eliminates distractions and IT maintenance associated with MS Windows

- Conserves space on the production floor

- Improves reliability of the overall test process