Customer

A worldwide leader in the design and manufacture of commercial and military helicopters.

Challenge

Perform stress testing on helicopter main rotor actuators by developing a system that simulates aircraft flight controls. Implement the flight control computer’s actual algorithms for command and control of the actuators. Provide a hardware interface consistent with the flight hardware. Maximize test coverage and capability.

Perform stress testing on helicopter main rotor actuators by developing a system that simulates aircraft flight controls. Implement the flight control computer’s actual algorithms for command and control of the actuators. Provide a hardware interface consistent with the flight hardware. Maximize test coverage and capability.

Solution

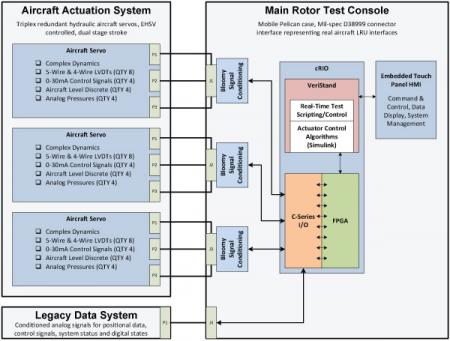

Bloomy and the helicopter manufacturer collaborated to design a flexible main rotor actuator hardware-in-the-loop (HIL) test system using predominantly commercial, off-the-shelf hardware and software. The system is comprised of National Instruments (NI) CompactRIO, NI MXI-Express RIO, NI VeriStand, as well as Bloomy’s signal conditioning and custom software. CompactRIO and MXI-Express RIO provide a high-performance embedded platform for data acquisition and control. NI VeriStand provides seamless Simulink model integration for implementing control algorithms, and Bloomy custom software provides system interfaces for visualization, data logging and system management. Signal conditioning electronics designed and manufactured by Bloomy supply the robust interfaces to complex sensor demodulation required by sensors such as linear variable differential transformers (LVDTs). The design supports both the helicopter manufacturer’s legacy data acquisition test stands through conditioned analog signals for every parameter, as well as modern new test stands via a digital control interface. This combination allows system control via local interface panel, legacy data systems or remote host.

Features

- HIL system for real-time rotor actuator test

- Controls three triplex-controlled aircraft actuators

- Requires no flight control computers

- Reduces test system development cost

- Simulink control algorithm integration

- Multiple signal types and quantities

- 3kHz LVDT – x24 (4 and 5 wire sensors)

- 0 to 30mA control signals – x12

- 28V discretes – x12

- 0 to 10V pressure signals – x12

- 0 to 10V conditioned readbacks for legacy data system – x62

- Custom LVDT signal conditioning

- Power amplification

- Filtering

- Embedded touch panel HMI

- Real-time test stimulus execution

- Mobile Pelican-brand case footprint

- Mil-spec D38999 connector interface representative of end application

Results or Benefits

The Main Rotor Actuator HIL Test System allows the helicopter manufacturer to perform stress testing and failure mode simulation on rotor actuators without consuming costly flight control computer resources and engineers. The NI VeriStand engine enables real-time stimulus of the actuator with arbitrary control signals. This capability maximizes the flexibility of the test platform by allowing the simulation of high-fidelity, nominal control signals as well as those caused by simulated system failures and unexpected states. Leveraging these capabilities has allowed the customer to generate a much wider range of quantifiable, repeatable and complex system failure simulations. Prior actuator test systems required significantly higher design and development costs and achieved a fraction of the coverage provided by this system.