HIL simulation is well-known in the automotive industry, enabling engineers to test embedded systems by simulating real scenarios.

Cost and functionality factor into any design and development phase of a system: “HIL testing is invaluable because it allows these dangerous or difficult tests to be conducted with a great deal of fidelity, which saves cost and improves safety and reliability,” says Bill Eccles, principal electrical engineer at automated test, data acquisition, and control system manufacturer Bloomy in Hartford, Connecticut. “Though manufacturers always test their products in the real world, there’s simply no way they can exercise them in all conditions.”

Cost and functionality factor into any design and development phase of a system: “HIL testing is invaluable because it allows these dangerous or difficult tests to be conducted with a great deal of fidelity, which saves cost and improves safety and reliability,” says Bill Eccles, principal electrical engineer at automated test, data acquisition, and control system manufacturer Bloomy in Hartford, Connecticut. “Though manufacturers always test their products in the real world, there’s simply no way they can exercise them in all conditions.”

The scalability and maturity of this technology has enabled aerospace and defense companies to use HIL simulation to test RF signals. “That’s pretty revolutionary that someone is using HIL with RF signals,” says Adam Foster, senior product manager for test systems at National Instruments in Austin, Texas. “HIL is a big thing for aerospace and defense. It allows them to go after more corner cases in complex situations.”

HIL subjects the part “to signals and conditions similar to those found in the real world. These signals are under the control of models of the real world, which run in a real-time test environment,” says Eccles. The part “then produces signals which feed back to these models, and that makes a complete loop. The result is that the flight control, system computer, engine control, or whatever ‘thinks’ it’s happily flying or rolling along even though it’s stuck on a rack in a lab somewhere.”

Using HIL testing for aircraft

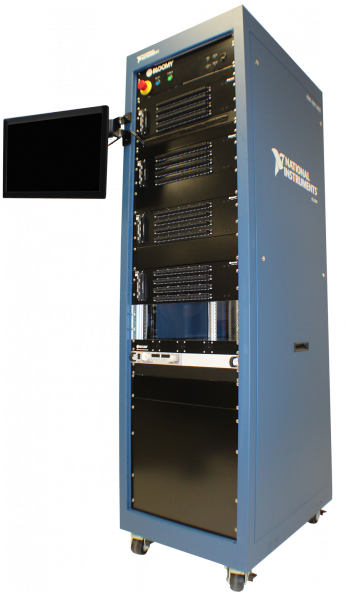

With airborne platforms, such as Saab Aerospace’s Gripen fighter aircraft, engineers used National Instruments’ HIL-simulation technology (Figure 1) for integration testing of its LRUs. “Saab Aerospace is focusing on HIL simulation to help drive down cost. Aircraft simulations can be done using physics models and using signal processing. It’s not all software but it does require some hardware functionality in it,” Foster says. “There are certain safety factors; you want to ensure you have as much test coverage in as many of the corner cases that this vessel or instrumentation could be put in.”

Figure 1: HIL simulation can be customized through open software, modular PXI and CompactRIO instrumentation, and signal conditioning (SLSC) modules. Photo courtesy of National Instruments.

Figure 1: HIL simulation can be customized through open software, modular PXI and CompactRIO instrumentation, and signal conditioning (SLSC) modules. Photo courtesy of National Instruments. Some simulations the aircraft can be placed in could be, for example, “If your airplane has engine failure, you need to be able to simulate how ECUs or LRUs are going to behave in these situations,” Foster continues. “HIL lets you simulate those things without having to do all of the physical tests for it. So you’re not going to have to build a prototype and staff it with somebody flying it and force them to do a nose-dive or blow up one of the engines.”

Essentially, “HIL tricks the LRU, or ECU, or onboard control unit into thinking it’s actually flying, and so it requires a lot of sophisticated instrumentation both to send the stimulus signal as it would be recorded or determined from physics models or recorded from empirical data,” he says.

Testing the aircraft requires the engineer to understand every minute detail of the aircraft, from what type of material the wing is made of, to how fast the airplane will go, to what the wind conditions look like with humidity, Foster explains. “All that simulation and information requires an immense amount of processing power, but what you do is you basically plug in the ECU and run it through various permutations of flying conditions and failure modes, all while you’re logging data.”

As software becomes more prevalent, the “microtrend of hardware-in-the-loop would be as we digitize everything, and as we switch from mechanical control to electronic control, you get the ability to test it and continue to squeeze cost out of it. All the while you are creating physics models and running simulations that would give you very reliable results between simulated and real,” he adds.

Source

Website Article

Iriarte, M., “Hardware-in-the-loop simulation testing for defense and aerospace systems,” Military Embedded Systems, September 2016. Retrieved January 13th, 2017 from http://mil-embedded.com/articles/hardware-in-the-loop-simulation-testing-defense-aerospace-systems/

Related Links