Real-time HIL test of flight control systems for rotary- and fixed-wing aircraft

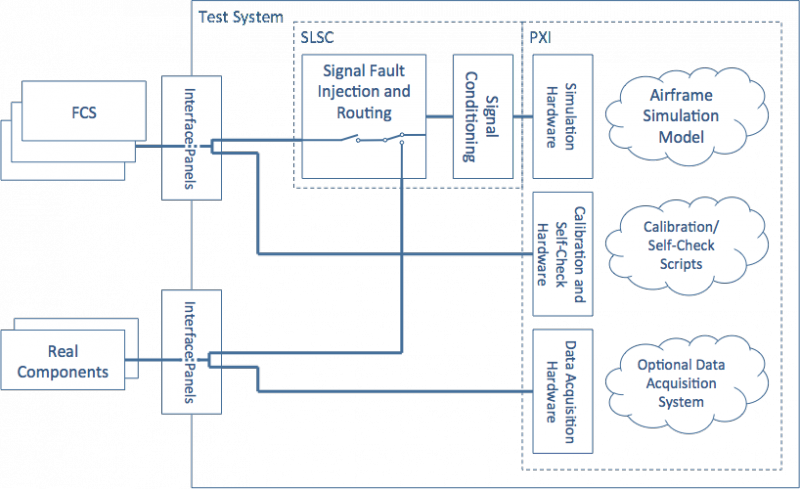

The Flight Control System Test Platform provides a hardware in-the-loop (HIL) closed-loop test environment for dynamic and maintenance testing of Flight Control Systems (FCS) of both commercial and military aircraft. The system simulates control surface activities from multiple combinations of rudder, flaps, elevator, aileron, and engine controls to the FCS. The system delivers repeatable, cost-effective testing in a fraction of the time needed with typical in-house simulation test systems.

The extensive set of I/O channels in the FCS Test Platform meet the requirements for flight control systems in large commercial and military aircraft. The number and type of I/O can be reduced or expanded to the exact requirements for any type of airframe. Customer-proprietary simulation models of the avionics systems are easily incorporated into the test system software for comprehensive test coverage. The system may be used standalone or as part of a larger System Integration Laboratory (SIL) or Iron Bird.

The test system is based upon the Bloomy Simulation Reference System, which reduces overall lifecycle costs and creates a common test platform for HIL test systems in a System Integration Laboratory (SIL). The reference system includes industry-standard components from National Instruments, The MathWorks, Virginia Panel Corporation, and Bloomy. These components are used in other Bloomy Test Platforms including the FADEC/EEC Test Platform and the Environmental Control System Test Platform.

Bloomy's Flight Control System Test Platform can be used in a range of test system applications including:

- Flight control system, including, "Fly-by-wire" verification and validation

- Development, production, or maintenance testing

- “Fly the Box” test of customer return material

- Development of control laws prior to physical airframe test

- Reduces physical test requirements

- Minimizes dangerous fault conditions in physical test

- Environmental Stress Screening(ESS)/Highly Accelerated Life Testing (HALT)

- System Integration Labs (SILs)

Bloomy's Flight Control System Test Platform features include:

- Simulation environment for comprehensive flight control system testing

- Analog I/O including thermistor, RTDs, strain gages

- Actuator loads including inductive solenoids, torque motors, and indicator loads

- Discrete switch signals, including open/ground, open/Vcc, open/closed, and customizable high-resistance state

- Available digital communications including ARINC-429, MIL-STD-1553B, FireWire, AFDX, serial

- Simulation-controlled variable DC power supplies; optional 1Ø/3Ø AC supplies

- ThroughPoint™ Interface Panels with integrated breakout box functionality and high-reliability Virginia Panel interface connectors

- Optional real/sim. switching for testing real actuators with the system

- VeriStand real-time framework for integrating customer-supplied gas path and other models

- TestStand test executive and LabVIEW programming environment

- Self-test for rapid system checkout and troubleshooting

- Optional data acquisition for incorporation of real-world parameters into testing

- Standard configuration for out-of-the-box functionality with typical ECSs

- Highly-customizable architecture and interfaces to meet user-defined requirements

| Signal Conditioning and Communication I/O | |

|---|---|

| Interface Type | Channels |

| VDT/Resolver simulation (4W, 5W, 6W)*+ | 8 |

| Thermocouple simulation*+ | 8 |

| RTD simulation*+ | 8 |

| Thermistor simulation+ | 8 |

| Strain Gauge simulation+ | 8 |

| Loads (torque motors, solenoid, lamp, etc.)*+ | 16 (8x <5W, 8x >5W) |

| Discretes (one-wire and two-wire)+ | 32 |

| Differential analog outputs to UUT+ | 8 |

| Potentiometer/variable resistor simulation | 8 |

| RS-422 | 2 |

| ARINC-429 | 8 |

| AFDX/ARINC-664 | Optional |

| MIL-STD-1553B | Optional |

| IRIG B | 1 |

| Ethernet Test Bus | Optional |

| DC Power | 2 |

| AC Power | Optional |

| Fault Insertion | |

|---|---|

| *Open circuit fault included. | |

| Other fault conditions (short to ground, pin to pin short, etc.) optional for all signal types |

| Self-Test | |

|---|---|

| +Self-test standard, calibration optional | |

| Loopback self-test optional for all other signal types |

| Computing Resources | |

|---|---|

| Real-Time Simulation Host | PXIe-based, RTOS, up to 8-Core Xeon |

| Instrumentation and System Management | PXIe-based, Windows, up to 8-Core Xeon |

| Software Environments | |

|---|---|

| Real-time Framework | National Instruments VeriStand |

| Test Executive | National Instruments TestStand |

| Data Acquisition and Programming | National Instruments LabVIEW, C/C++ |

| Data Management and Analysis | National Instruments DIAdem |

| Software Models | 23 model types, including LabVIEW, Simulink, MatrixX, C/C++, MapleSim |

| System Dimensions and Power | |

|---|---|

| System Chassis | 1- or 2-bay 40U equipment racks |

| 1-bay: | approx. 78"H (with locking casters) x 23"W x 36"D |

| 2-bay: | approx. 78"H (with locking casters) x 46"W x 36"D |

| Weight | Configuration dependent |

| Power Requirements | Power requirements vary with selected Ac and DC power supply options |

| Emergency Power Off | Standard |

| Uninterruptible Power Source | Standard for all computing resources |

| Warranty | |

|---|---|

| 1-year warranty on all hardware components, optional extended warranties available | |

| 3-year software service plan on all National Instruments software products |