12 Isolated 500 mA Channels in 1 RU

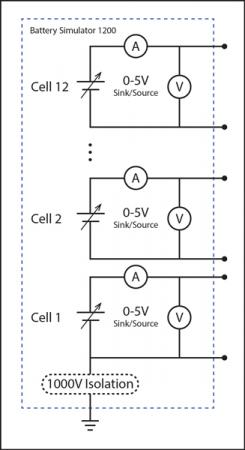

The Battery Simulator 1200 provides twelve programmable cell channels that sink and source current for testing battery management systems (BMS) and battery-sensitive electronics. The cell channels are isolated to enable series connections for simulating battery modules, strings and packs. The instrument is controlled from a computer connected via Ethernet or high-speed CAN. The 1U rackmountable instrument can operate on a benchtop or stacked within a 19” rackmount enclosure. A soft front panel provides easy access to the unit for basic testing and initial startup, while software drivers and CAN database are ideal for automated test system integration. Built-in voltage and current readback sensing provide accurate cell voltage measurements and control without external monitoring equipment. The Battery Simulator 1200 is FCC and CE certified and relied upon by electrification companies globally.

- 12 independently-controlled cell channels

- Sink and source 5 VDC and 500 mA per channel

- 1000V cell channel isolation *

- Auxiliary analog and digital I/O

- Ethernet and high-speed CAN control communications

- Soft front panel executable software

- NI LabVIEW™ drivers, CAN dbc

- FCC, CE certified

The Battery Simulator 1200 (BS1200) provides a safe and efficient means for electrification companies to simulate a broad range of battery cell and pack conditions in order to test battery management systems and other battery-sensitive electronics, without the hazards of real batteries. The twelve simulated cell channels have individually-programmable cell voltages and currents, allowing you to create an extremely wide variety of test conditions in order to comprehensively exercise the functionality of the device under test. Furthermore, the Battery Simulator 1200 allows you to simulate conditions that may be difficult, time consuming, unsafe, impractical or impossible using real battery cells. The Battery Simulator 1200 is a fundamental building block of many automated test systems, including Bloomy’s own family of BMS test systems.

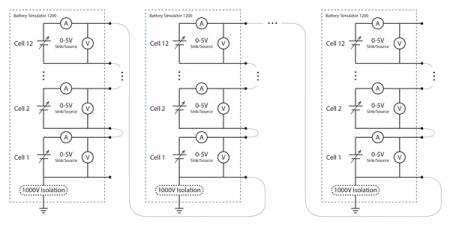

The Battery Simulator 1200 is housed in a 19 in 1U (1.75”) rackmount enclosure, which is ideal for benchtop as well as rack-and-stack test system integration. The isolated cell channels from multiple units may be connected in series in order to simulate a module, string or pack. In addition, auxiliary analog and digital outputs may be used to simulate thermistors, current sensors or contactors. The Battery Simulator 1200 is remotely controlled from a computer or CAN controller via Ethernet or high-speed CAN communications interface. The instrument comes standard with a soft front panel executable, NI LabVIEW drivers, and CAN dbc. The instrument is FCC and CE marked and relied upon by electrification companies throughout North America, Europe and Asia.

Learn more about Bloomy’s complete BMS test offerings:

| Cell Channel Simulation | |

|---|---|

| Number of Channels | 12 |

| Channel Type | Sink and Source |

| Voltage Range | 0.0 to 5.0V |

| Voltage Resolution | 0.1 mV |

| Voltage Accuracy (requires remote sense) | ±3 mV |

| Current Range | ± 500.0 mA |

| Current Resolution | 0.1 mA |

| Current Accuracy | ±4 mA |

| Current Limiting Accuracy | ±10 mA |

| Isolation | 1000V * |

| Channel Readback | |

|---|---|

| Voltage Resolution | 0.1 mV |

| Voltage Accuracy | ±3 mV |

| Current Resolution | 0.1 mA |

| Current Accuracy | ±4 mA |

| Digital I/O | |

|---|---|

| Channels | 8 (bidirectional) |

| Logic Level | 3.3V |

| Analog Input | |

|---|---|

| Number of Channels | 8 (single–ended) |

| Max Voltage | 5.0V |

| Voltage Resolution | 0.1 mV |

| Voltage Accuracy | ±5 mV |

| Analog Output | |

|---|---|

| Number of Channels | 2 |

| Voltage Resolution | 0.1 mV |

| Voltage Accuracy | ±5 mV |

| Max Voltage | 5.0V |

| Max Current | 10 mA |

| Control | |

|---|---|

| Communications | LAN, CAN |

| Drivers | NI LabVIEW™ |

| Max Control Rate | 200 Hz |

| Physical | |

|---|---|

| Dimensions | 19” W x 1.75” H x 15” D (1U) (482.6 mm W x 44.5 mm H x 381.0 mm D) |

| Weight | 7.5 lb (3.4 kg) |

| Operating Temperature | 0 - 35°C |

* Precautions are required for voltages exceeding 140V. Please refer to Application Note 8700-00038: Using the Battery Simulator 1200 in High-Voltage Applications.

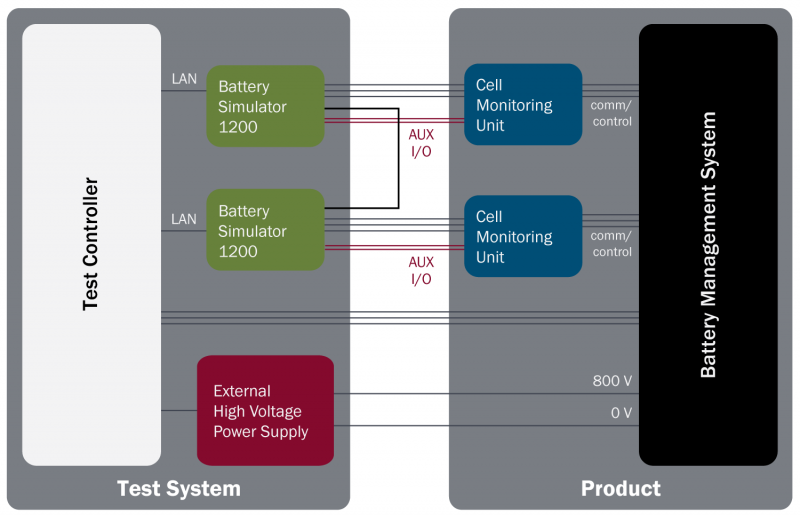

The Battery Simulator 1200 can be used in many test scenarios where stacked as well as series-connected cell simulation is required. Below is an example of integrating two Battery Simulator 1200 instruments and an external high-voltage supply into a test system. The two Battery Simulator 1200 instruments simulate 24 cell voltages and balancing currents to a cell monitoring unit (CMU). The high-voltage supply simulates an overall pack voltage of 800V. The auxiliary I/O is used for temperature and control I/O simulation.

Do you have a specific application? Contact us.

The Battery Fault Insertion Unit (FIU) provides intelligent switching of cell simulation channels for the Battery Simulator 1200. The switching capability enables simulation of open circuit and short-to-rail fault conditions on any cell channel for the purposes of Battery Management Systems (BMS) testing.

|  |

| Front of Unit | Back of Unit |

The Battery Simulator 1200 shipping software consists of LabVIEW drivers, a CAN dbc file, and a soft front panel. The soft front panel is an executable Windows PC application that allows you to connect, monitor and control one or multiple Battery Simulator 1200 instruments over CAN and Ethernet interface ports. The intuitive interface provides interactive monitoring and control of cell voltages and currents as well as accessory analog and digital inputs and outputs. Instrument communication settings, including CAN or Ethernet mode as well as Box ID or IP address can be changed programmatically. A drop down menu allows the user to select, monitor and control each instrument, one at a time.

Documentation

BS1200 Communication Specification

Application Note 8700-000378: Using the Battery Simulator 1200 in High-Voltage Applications

Drivers

LabVIEW Driver Version 3.0 for the Battery Simulator 1200

Python Driver for PEAK Systems PCAN USB Interface

Software