Customer

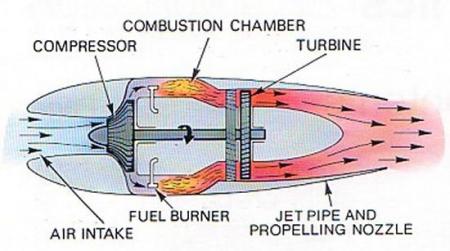

The Jet Burner Test Lab of United Technologies Research Center tests combustor sectors, scramjet combustors, augmenter sectors, vane cascades, rotating components,

fuel reformers, and fuel nozzle/swirler combinations for companies serving the aerospace propulsion market.

Challenge

Develop a multiple cell data acquisition system capable of acquiring and storing jet burner data from an assortment of hardware. Costly devices must be shared among test cells via the network, and channels must be calibrated and displayed in a common live data view.

Solution

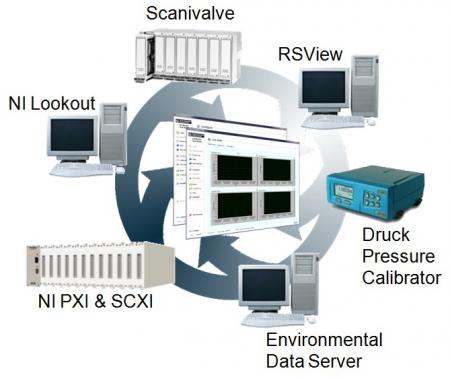

- 12‐slot SCXI‐1001 chassis connected via PXI‐6281 and an MXI‐4 data link

- Multiple data collection PCs distributed throughout facility serve data over TCP/IP

- Custom software developed using NI LabVIEW using a reusable shell for handling user login, event logging, and screen navigation

Features

- Acquires 128 thermocouple, 32 bridgeamplified, 128 differential pressure, 16 frequency, and 32 high‐level voltage channels

- Gathers emissions data from NI Lookout, control data from RSView, and barometer/dewpoint data from an environmental data server PC

- Automatic pressure channel calibration using remotely controlled Druck pressure standards

- All data sources are configurable through a unified channel configuration interface

- Dual‐mode data acquisition speeds allow for on‐demand switching between Continuous (up to 100 Hz) and burst (up to 20kHz) acquisition for capturing transient features on‐demand

- Automatically names and organizes data files based on channel type

Results

The new data system provides a flexible means for bringing all channels in to a common interface. Automatic and manual calibration features speed the calibration process and reduce human error. File‐based configuration and calibration data allows for maintaining an archive for later reuse or customization of multiple test rigs. Each individual data acquisition system shares many resources over the network so that duplicate hardware is not necessary.